Knowledge

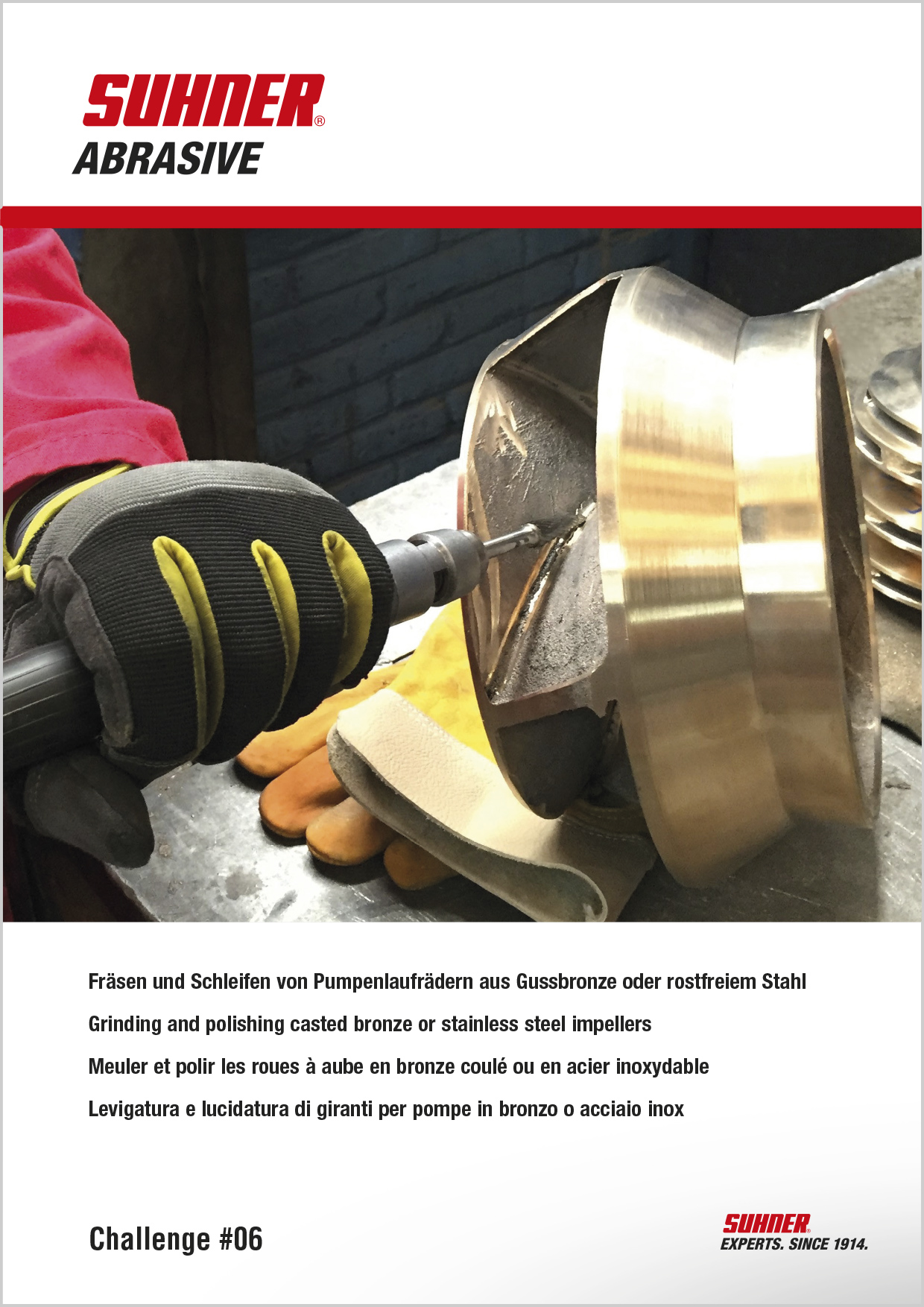

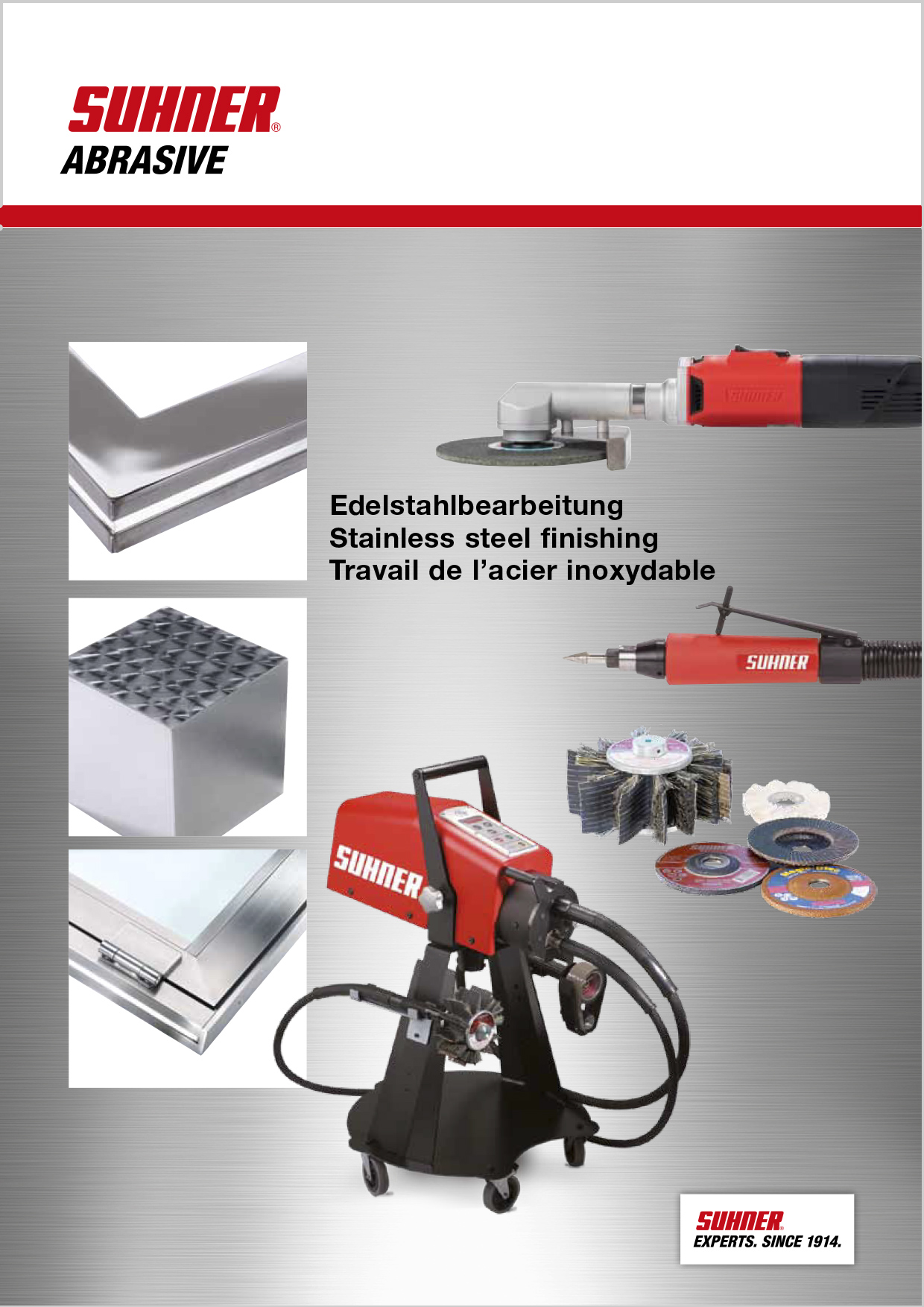

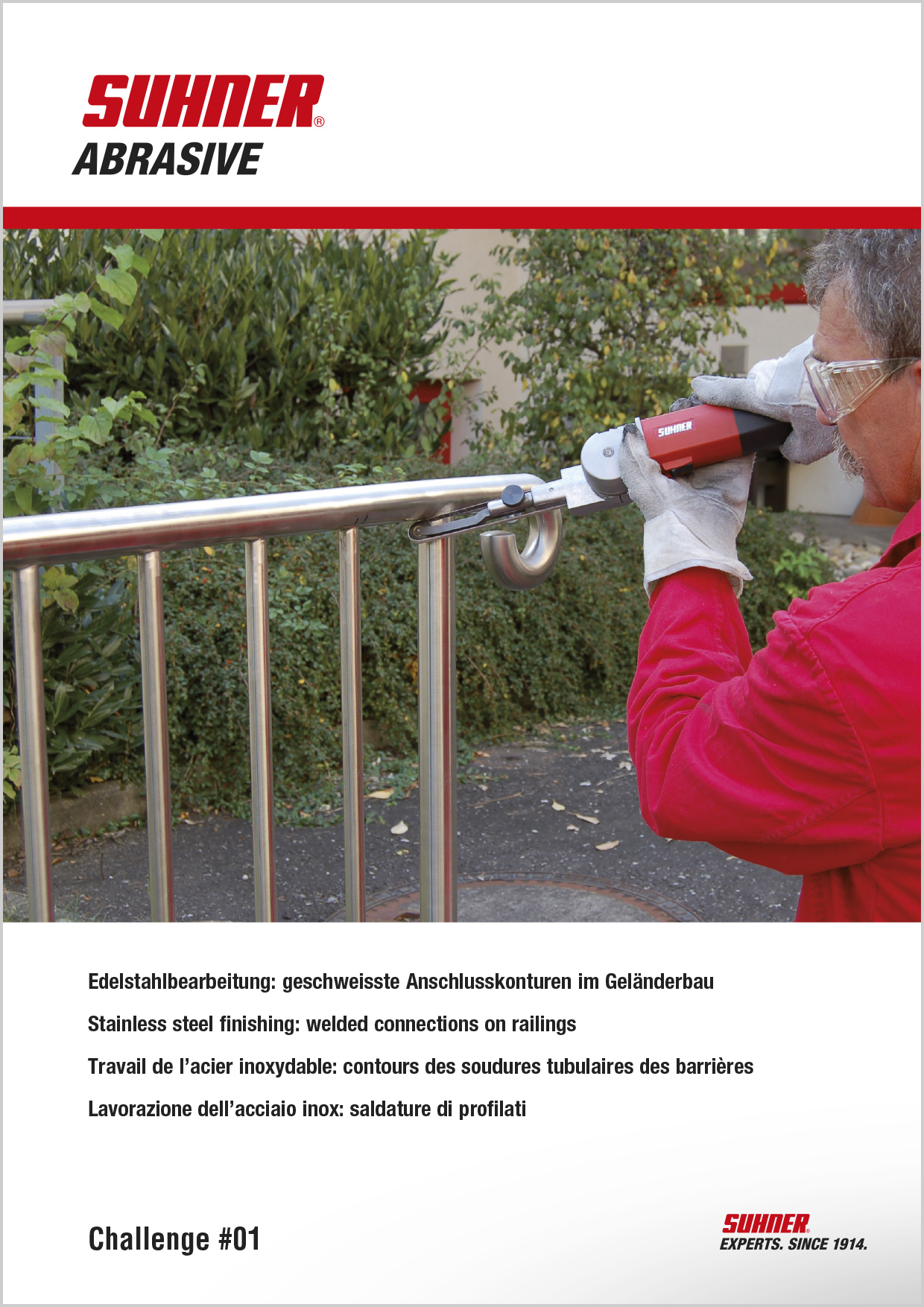

Application-oriented Solutions

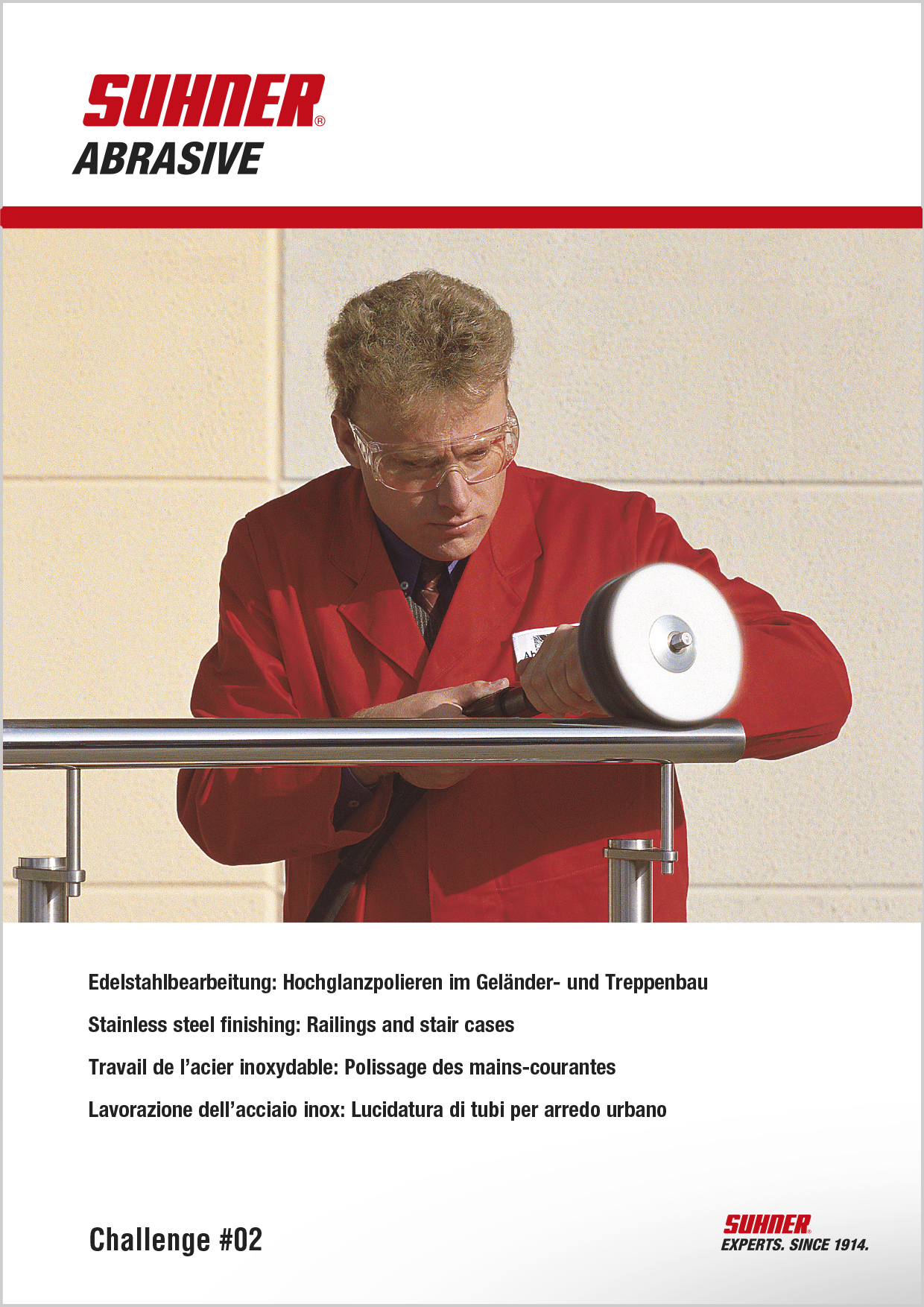

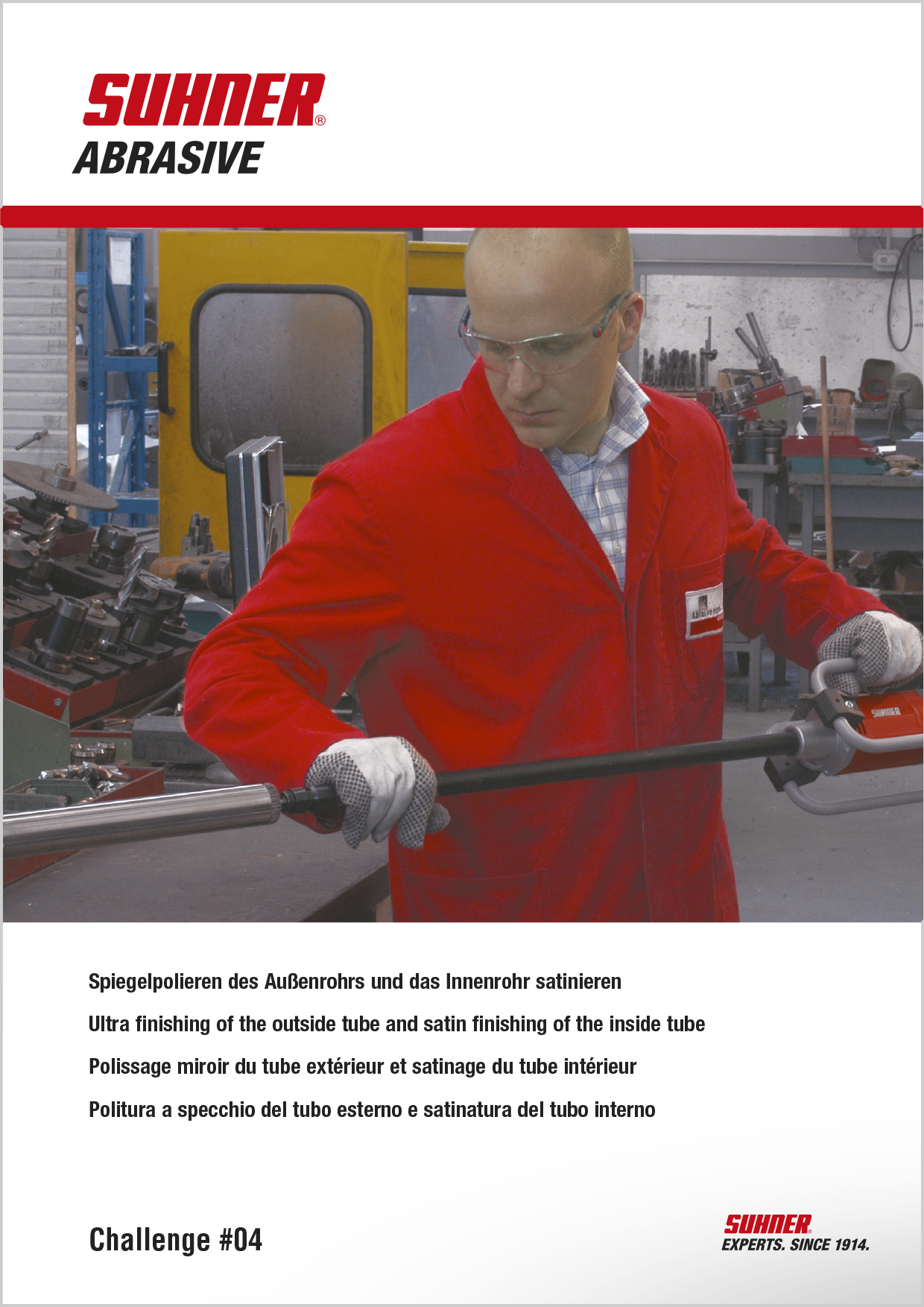

In order to make your work easier for you, we have prepared different solutions to known grinding tasks together with our customers. Fast and efficient to the required solution.

Videos - fast and efficient to the required result

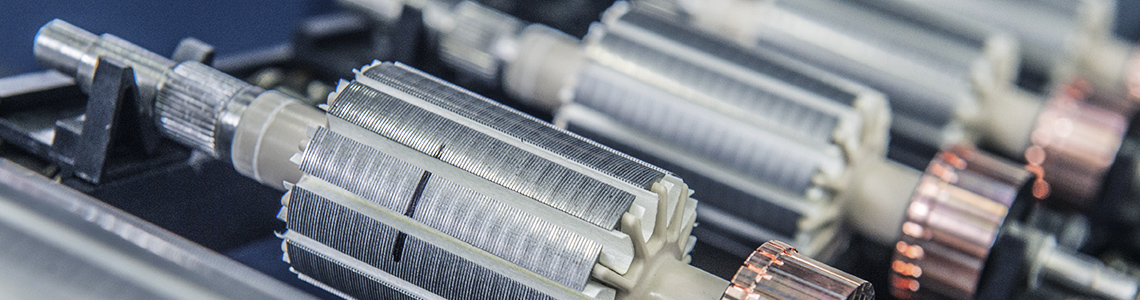

Competence in Motor Production

Power units - tailored to your needs. Do you need motors which are tailored especially for your requirements? Then you are in the right place with our company.

For more than 80 years Suhner has constructed, developed and produced motors that are proving their potential in every field of craft and industry.

At Suhner you will find motor winding and construction of prototypes, series manufacturing and fitting all under one roof. Highly qualified Engineers are working on your requirements with 3D CAD.

The tailor-made motors are based on existing standard components and are assembled according to customer-specific requirements and fulfill all the requirements for reliability, performance and efficiency.

During the whole process prototyping is essential. Suhner guarantees the sampling inspection of prototypes within the shortest possible time. Rapid prototyping allows the results to be checked and adapted efficiently during the development process.

The Motor range includes compressed air drives of performance class 110 - 900 watts and mainly universal electric motors of 300 - 2,000 watts in almost every voltage required in the world.

Energy Efficiency

Energy efficiency is a catchword that has not lost any of its current relevance. Although the minimum energy consumption and/or duty cycles of diverse products may render this discussion of energy efficiency a moot point, it is certainly highly relevant for economical and efficient machining on surfaces with aggressive abrasives and long duty cycles.

Follow us on